Shanghai Kaiwei is a renowned tech enterprise who are spearheading innovation covering numerous countries all around the world. They are known for their Form in Place Foam Gaskets machines, Plate spraying machines, Injection Potting Machines, and beading machines, a.k.a PU foam sealing machines.

Lets delve into some applications of these Gasket forming machines below.

Form-in-place gaskets are created by applying liquid polyurethane sealing foam to metal or plastic parts prior to assembly. Because it is dispensed as a PU liquid this ensures a precise fit, even in places of housing imperfections. The resulting seal is both reliable and durable.

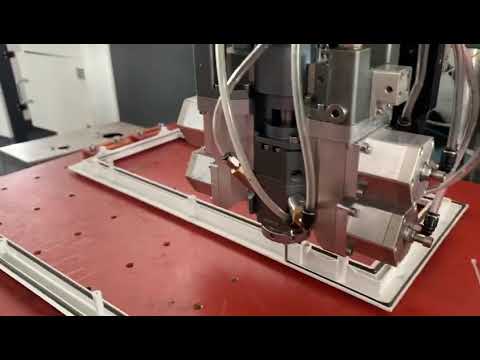

Our Kaiwei machines are designed for the precise dispensing of FIP gaskets using CNC machines.

This impressively accurate process will allow you to work on places with less than one-millimeter width, and they can still receive PU FLIP gasket application. These gaskets are an affordable, precise, and easy sealant solution.

Applications of PU FLIP EMI shielding for electronics

Surround sealing for dust/water protection

Sealing for adhesive reasons - simpler assemblies

Specific FIP Gasket usages

Electronics

-Satellite communication

-GPS systems

-Lighting

-Electronic enclosures

-Semiconductors

Medical Devices

-Heart pumps

-Dialysis machines

-Ventilators

-Oxygenators

Defense and Military

-GPS systems

-Radar

-Missile guidance

Communications

-Cellular devices

-WiFi routers

-Cellphone stations

Aerospace

-Airport ground equipment

-Drones

-Flight instrumentation

-Airplane seats

Mass Transportation

-Accessory components

-Mechanical equipment

-Seating

The Gasket is not only resilient, it's flexible too. It offers a highly versatile sealing that will stay put even in freezing water, heat, corrosion, UV and more.

PROS of FIP Gaskets

-Adaptability to various conditions

-Easy and fast to install. Once dispensed, there is no need for additional assembly work.

Dispensing Technology

The FIP gasket dispensing process is straightforward. Many manufacturers employ robotic systems to accurately apply the material along the specific paths on the housing.

Primary Gasket dispensing steps :

-I am inserting the PU liquid Chemicals into the gasket dispensing machine.

-The machine dispenses chemicals with the help of a needle and then applies the gasket bead onto the housing, and the dispenser moves along a specific path with the help of a CNC machine - metals/plastics.

-The PU FIP gasket is allowed to cure for a period to achieve a 2:1 ratio of liquid to solid.

-The FIP Gaskets are super resistant against heat, water, moisture, or UV light.

Some alternatives are available to FIP gaskets - Use of a pre-cut custom gasket. The catch is that manufacturers prefer automated gasket dispensing for accurate and cost-effective results.

Manual application of gaskets by hand is counterproductive and time-consuming.

Features of FIP Gasket Gasket dispenser

-Dosing and mixing automation

-Material sensors

-Needle tip calibration

-Vertical dispensing

-CNC dispensing

-Automated head cleaning

-Automatic rotation

CNC Gasketing machines are a no-brainer when it comes to electronic assembly and other simple small-scale manufacturing like doors and cabinets, etc. Form-in-place gasketing is impressively delicate and precise, which means it offers excellent quality protection.

Adaptable to multiple surfaces

Form - in Place, gaskets are applied directly to metal or plastic surfaces as they dispense silicon. This can give way to elevational changes, uneven surfaces as well as thin profiles. With sensing technologies like gasket self probing, Form-in-Place should be an excellent answer for even mediocre molded housings and cast metal sheets. Pre - dispensing inspection of the gasket shelf can significantly reduce costs by minimizing machining and housing rejects.

Small Gasket Dimension

Form-in-place facilitates electronic packaging with higher-density components because of their inherent ability to place even the tiniest possible bead within a small cross-section.

AUTOMATED PROCESS

Regardless of the size of the products, the robotic system that the form-in-place utilizes enhanced repeatability. This enables complex and impressive product design.

Form-in-place dispensing is excellent for the following cases:

Small, complex, and intricate gaskets

Environmental sealing for dust or water protection

Resistance to freezing, heat, UV, and corrosion

Fast assembly or short turnaround time requirements

Situations where installation of the gasket is complicated or would be made easier if the gasket was adhered to the part’s surface.

YES Machinery is much obliged to serve every industrial machinery solution by keenly observing each case scenario and need. We customize your problems and go beyond standard options.

We offer quality Polyurethane Foam Machines/PU Foam Machines that hail from China, manufactured by Shanghai Kaiwei, with customized solutions catered to all small, medium, and large productions that are used by a number of small-scale and big corporations.

PU foam machines are reliable tools that are used for a wide range of foaming applications, including rigid and flexible PU foam production. These offer impressive flexibility, versatility, and adaptability.

Talk to us about your doubts and thoughts, YES Machinery will find a customized solution for you, and don't forget to visit our showroom for a demo session and to talk to our industry experts in person.

China

China